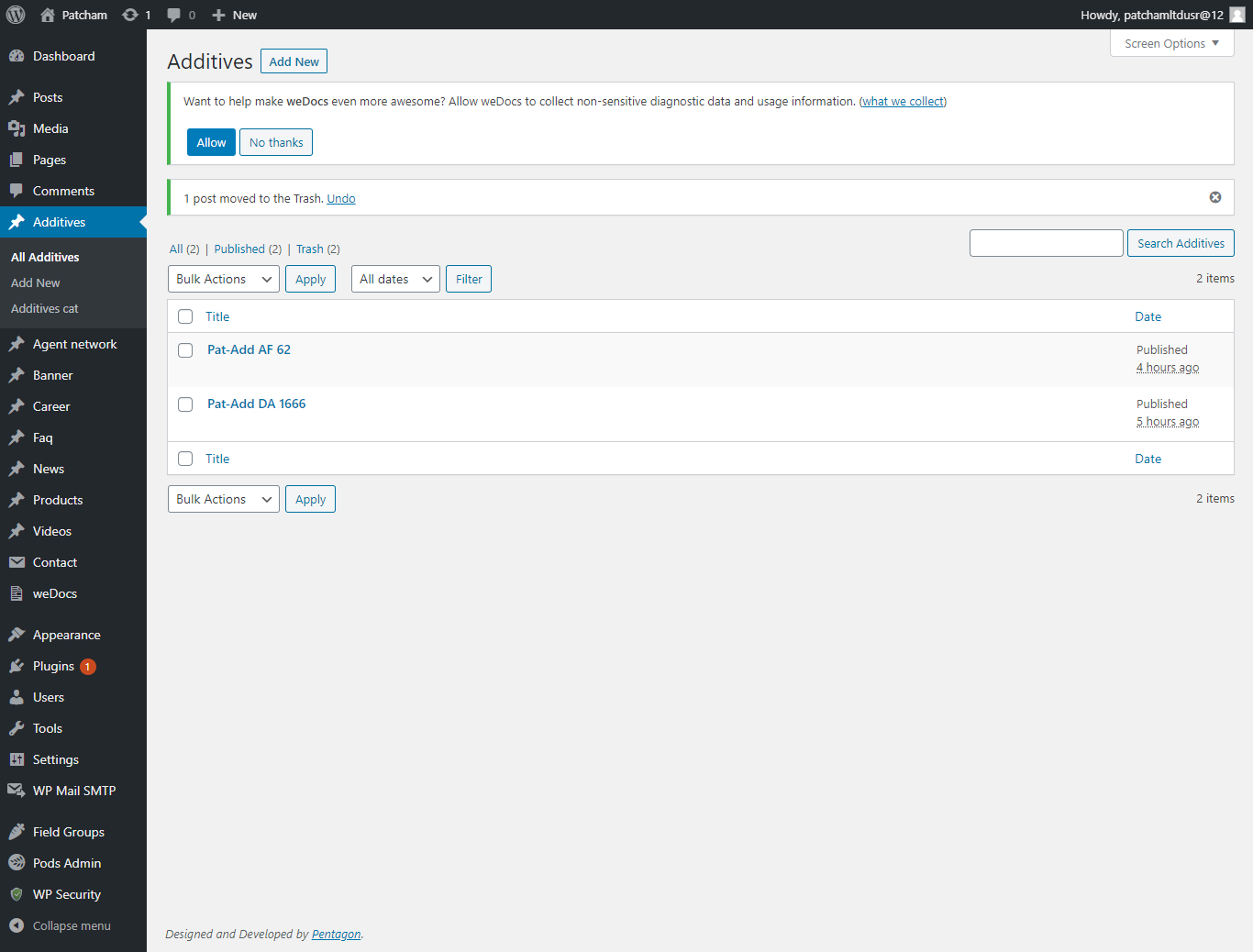

Admin can add, edit or delete Additives from here. All created Additives are listed here. The Additives can edit through Edit link and remove through Trash link

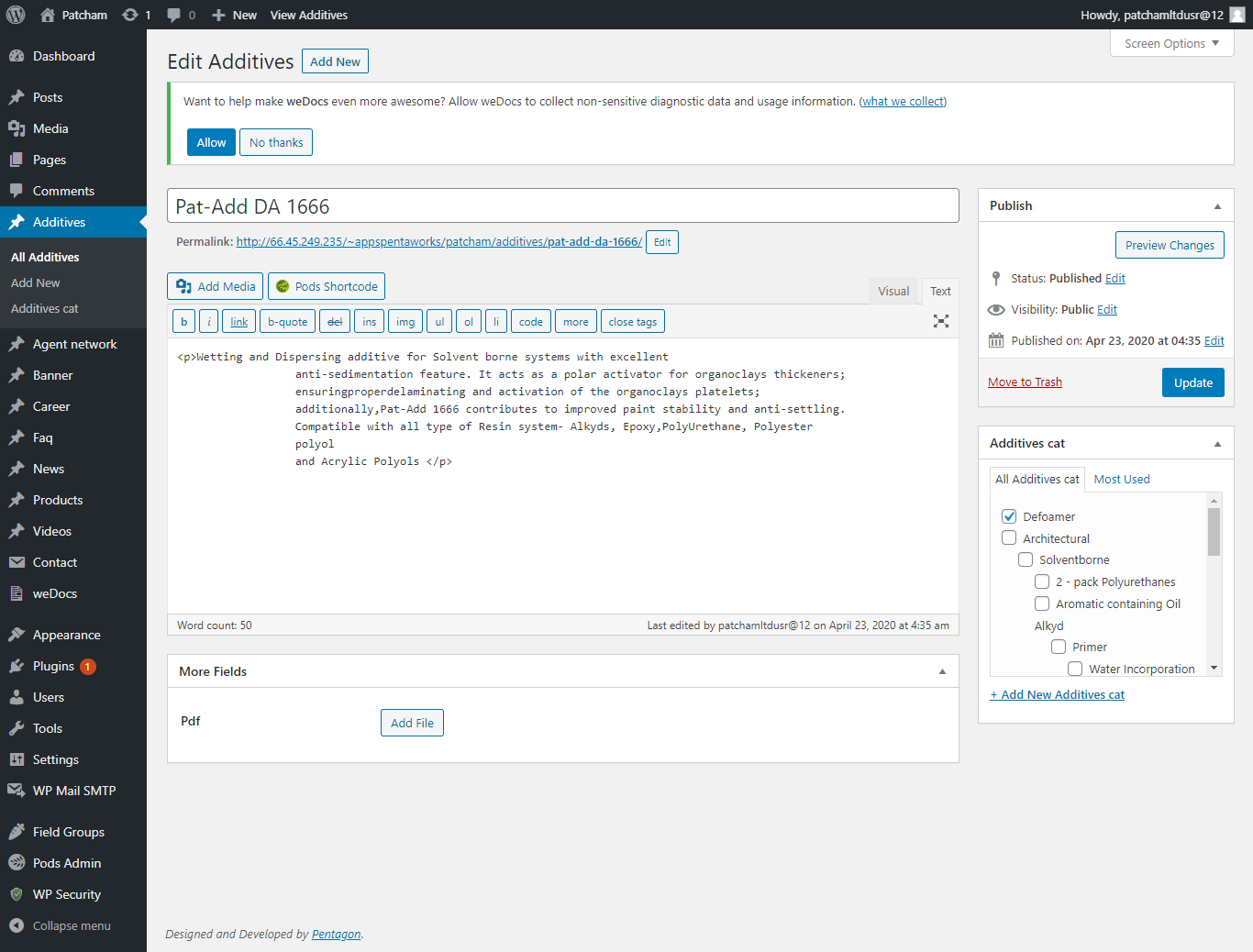

Clicking on Add New to add new Additives. We can upload images directly by clicking on the Featured Image link.